Design for Sustainability

Home → DFS Principle 3

Home → DFS Principle 3

In general, every manufacturing step requires some level of separation or purification or both. The separation and purification process typically requires significant amount of energy. For example, the paint shop in automotive assembly plant consumes 60% of the energy because the paint shop has to maintain a dust free environment with optimum air quality and room temperature.

One of the best ways to execute this principle is to have a robust design that allows contamination but still perform the required function/(s). If one cannot accept contamination, then design a filtering system to remove contaminants prior to entering the system. It will be very expensive, energy intensive, and time consuming to separate the contaminant once it enters the system.

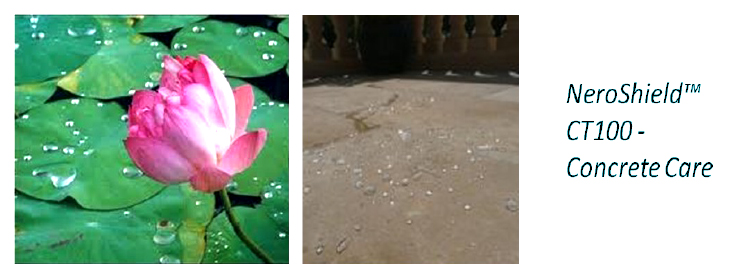

Lotus Effect

The lotus effect was first observed in the leaves of the lotus plant. Despite constant exposure to dust, dirt, and rain, the leaves of the lotus plant remain clean and dry. Scientists have learned discovered that the surface of each leaf contains nano-scale waxy bumps that prevent both dirt and water from adhering to it.

After understanding this phenomenon, scientists start thinking how one could mimic this "Lotus effect" and apply the Lotus effect to our daily technology. For example, raincoats and umbrella would perform much better if one could apply Lotus effect. In addition, paints incorporating the Lotus effect could keep houses and buildings clean and dry.